Description

These dimple dies have cosmetic imperfections with discounts assessed and applied. Imperfections may vary. Stock limited to what is on hand.

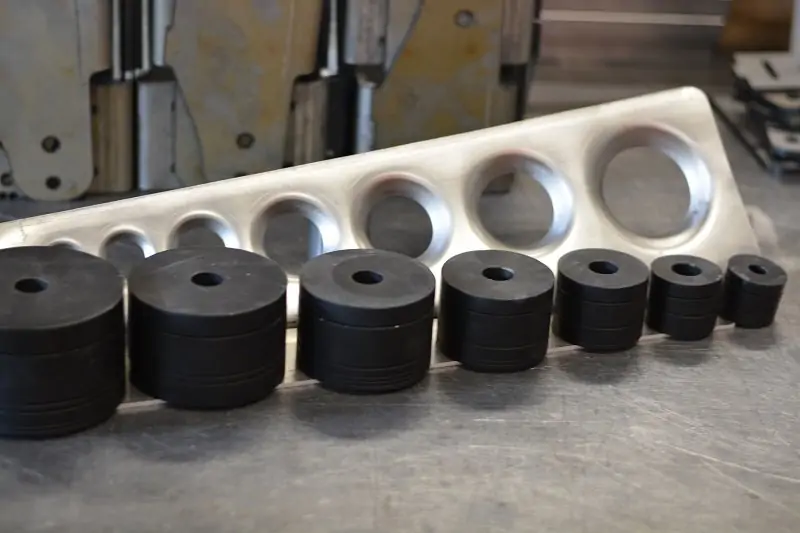

Quick ID has a wide groove for every inch and a narrow groove for every 1/4″, so a die with one of each groove is 1″ + 1/4″, so 1 1/4″. A die with 2 of each groove is 2* 1″ plus 2* 1/4″, so 2 1/2″. Now you can finally stop putting a tape measure on your dimple dies or writing on them!

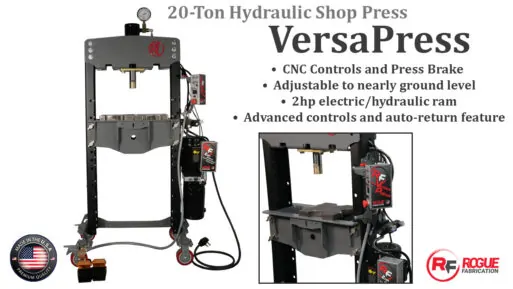

How to use: Cut your hole out with a hole saw or any other method of your choice. Use a bolt, H frame press, or knockout driver to dimple the hole with these dies.

These are CNC machined in the US out of 4140 Chromoly that is made and heat treated here is the US. Max capacity 3/16 inch plate steel. We know these aren’t the cheapest set, but they are the best! The coating on these dies is a high performance NICKEL for reduced friction. The prototype set in some of the photos is black zinc. It is not intended to be a cosmetically perfect coating, but it is a good rust preventative for industrial applications like dies.

See description of regular dimple dies in our store for what each size is. (Blem/Return) – This item has minor cosmetic flaws (scratches, slight dents, etc.) and performs 100% as good as a new unit. May have been returned or damaged in handling or shipping. See SCRATCH/BLEM/RETURN for more information (opens in new tab).

2 reviews for Round Dimple Die Scratch/Blemish – Quick ID