Description

New photos of all possible configurations coming SOON!

Hitch receivers are BORING! They used to all be the same, blending into a bland sea of bumpers and builds. Not any more! The Rogue Receiver revitalizes rear bumpers. It reinvents the reinforced front bumper hitch mount philosophy. Made from a combined .478″ (nearly 1/2″) wall thickness, this is a STOUT receiver tube. You can MIG or TIG weld yours and make your bumper stand out. These are a fun and challenging welding project (depending on your approach).

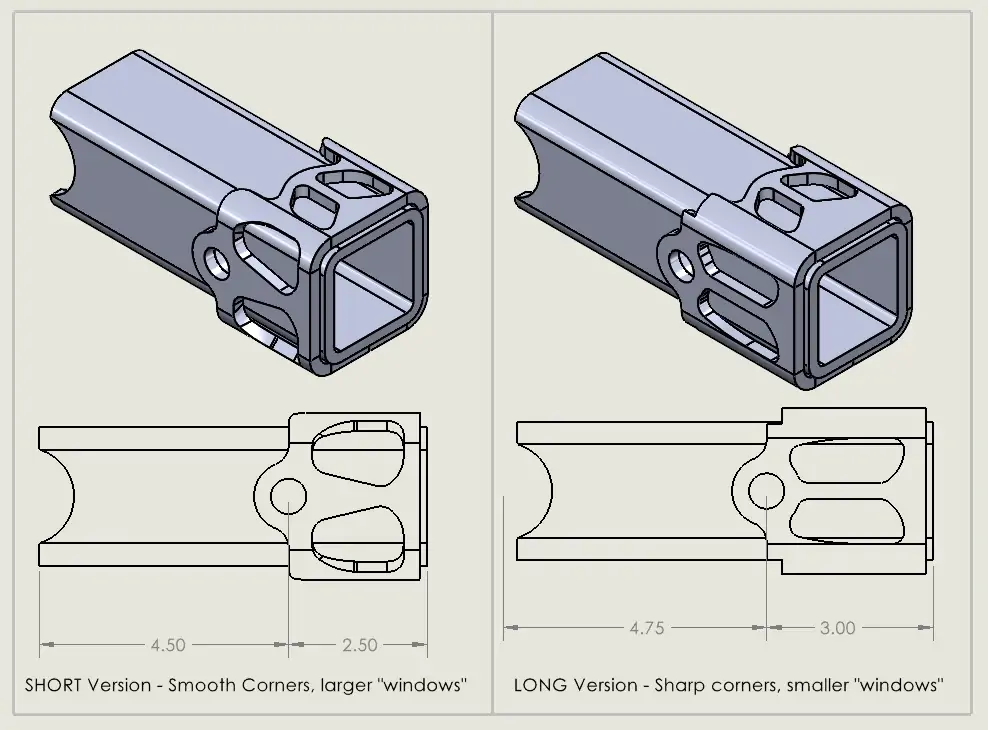

Variations:

Logo – Sleeve only: This is the outer sleeve (to reinforce your own hitch tube). Ships AS CUT. 3 sides with “feather” shaped cutouts, and one side with bolt pattern for one of our 2” logos. Comes with a 2″ RF logo!

Logo – Sleeve and tube: This is the outer sleeve and the hitch receiver tube. Ships AS CUT. 3 sides with “feather” shaped cutouts, and one side with bolt pattern for one of our 2” logos. Comes with a 2″ RF logo!

Logo – Sleeve and tube, weld prepped: This is the outer sleeve and the hitch receiver tube. Ships with the tube sanded for welding and the inner weld seam on the sleeve ground flush. We also press the two pieces together and ream the cross pin bores (if required). 3 sides with “feather” shaped cutouts, and one side with bolt pattern for one of our 2” logos. Comes with a 2″ RF logo!

No Logo – Sleeve only: This is the outer sleeve (to reinforce your own hitch tube). Ships AS CUT. All 4 sides with “feather” shaped cutouts.

No Logo – Sleeve and tube: This is the outer sleeve and the hitch receiver tube. Ships AS CUT. All 4 sides with “feather” shaped cutouts.

No Logo – Sleeve and tube, weld prepped: This is the outer sleeve and the hitch receiver tube. Ships with the tube sanded for welding and the inner weld seam on the sleeve ground flush. We also press the two pieces together and ream the cross pin bores (if required). All 4 sides with “feather” shaped cutouts.

Preparation notes: The outer sleeve is welded box tube. This has a seam, but most of the seam is cut out of the product from the tube laser that produces them. You will have to grind this seam flush before assembly (it takes us about 3 minutes with an air die grinder). The receiver tube is a hot rolled steel and is seam controlled, so it is smooth inside and out. We belt sand the sides to get them nice and square and clean off the mill scale for cleaner welding. These two pieces have matching dimensions (receiver is 2.5” OD, sleeve is 2.5” ID), so they are a TIGHT fit. We press them together with a standard shop press. Some additional sanding would also allow them to slide together freely. The pin bores are standard 5/8”, and are a much closer fit that the sloppy 11/16 holes in hitch receivers on the shelf in big box stores. Depending on your alignment, you may need to co-drill, die grind, or ream your bores after fitting. This is normal, and preserves the ability to manufacture a hitch with a nice tight fitting cross pin, which is essential to a quality finish and a high cross pin load capacity. The holes for the logo are undersized These are not DOT or state approved, and as such are recommended for off road use only.

Reviews

There are no reviews yet.