Description

Another industry first! Shaped dimple dies. Set your fabwork apart from the crowd or use just the right shape to get the most weight benefit possible from your dimpling. Triangular holes in your tube gussets or square holes in your tie plates will cut more weight than round holes.

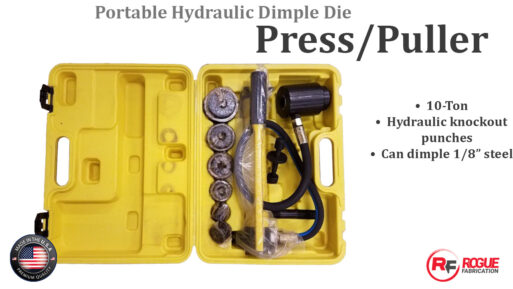

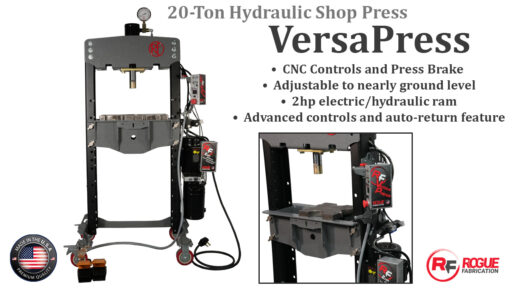

How to use: Cut your shape out on a plasma table, laser cutter, or with a grinder. Use a bolt, H frame press, or knockout driver to dimple the hole with these dies.

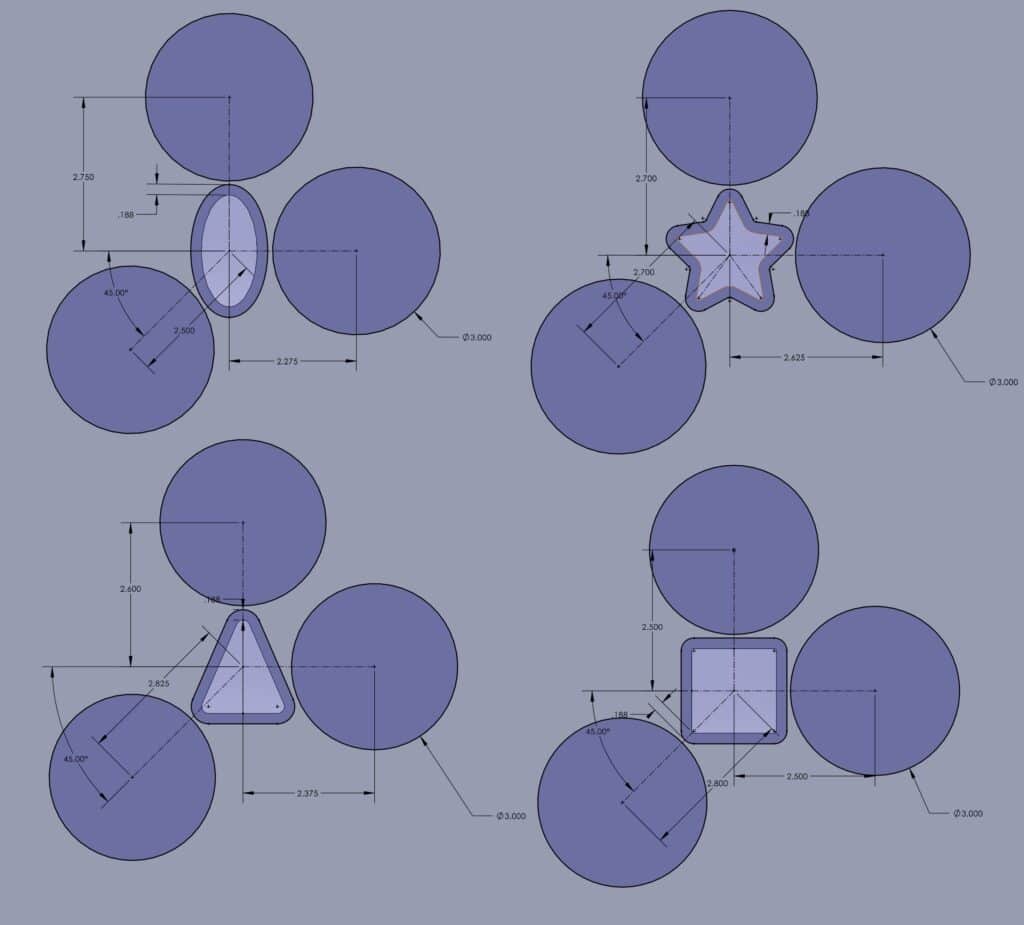

These are machined in the US out of 4140 Chromoly that is made and heat treated here is the US. Shapes are 1.5-2 inches tall. Max capacity 1/8 inch plate steel. If you are putting multiple triangles in a line, space them 2.20″ apart minimum (feature center to feature center) for best results.

Plasma cutter drag tip stencils are available for .188″, .270″, .385″, .430″, .580″, and .662″ tip diameter plasma cutters (for cutting shapes by hand).

We will e mail you DXF files of cutout shapes for your use after purchase.

Many users have asked us about minimum spacing between dimple dies. If you are placing dimples close to other features (like other dimples or bent flanges), you must allow for the 3″ diameter of the dimple die to not contact that feature. Here is an illustration:

2 reviews for Shaped Dimple Die Bundle