Description

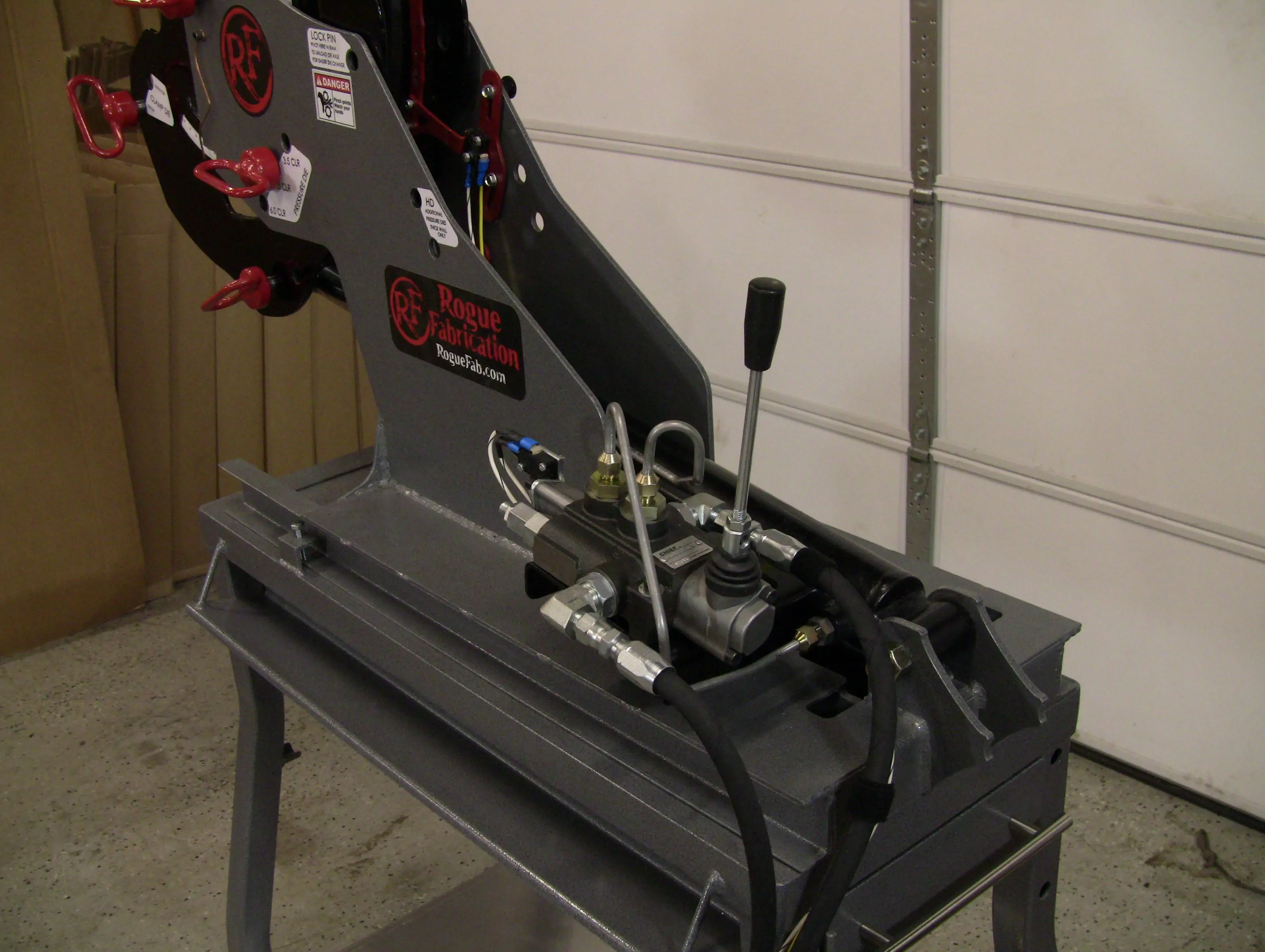

This is the more expensive of the hydraulic systems that can power a model 600 series tubing bender. It is also the highest performance.

Currently, our lead times are approx—5-12business days.

As of 1/10/2025, all systems come auto-stop ready; the only need to auto-stop the component bag is to have a working auto-stop. All non-auto-stop purchases before this date are not auto-stop ready and would need a custom order to convert. Please get in touch with us if you’re interested.

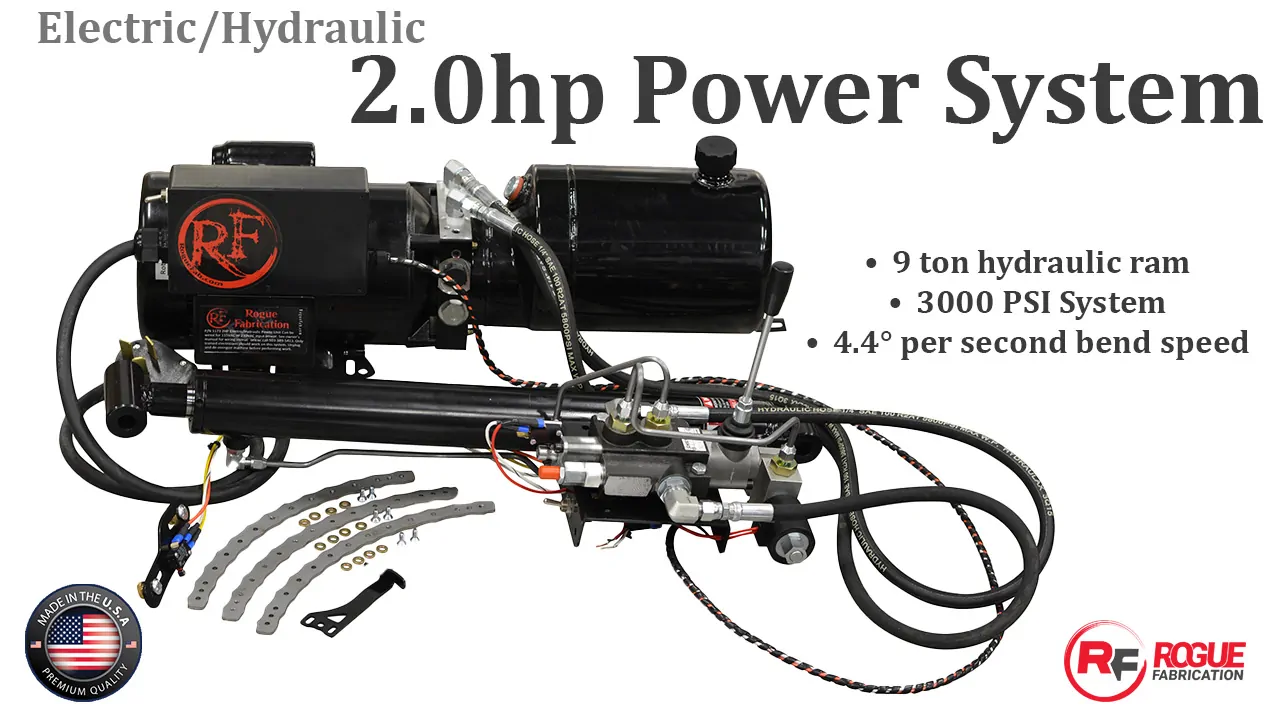

This 3000 PSI electric/hydraulic system was fully engineered to work with our bender. It features a 2 H.P. industrial induction motor, a robust pump and steel reservoir, and a custom ram. This is the most affordable high-performance automatic electric hydraulic power system on the market. We make these systems right here in the US with 99% of the components being sourced from North America and Europe.

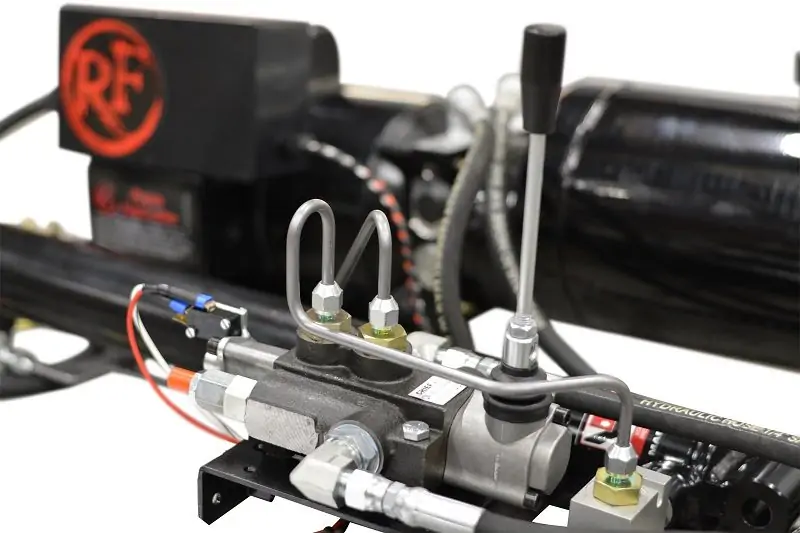

Bending speed: 4.4 degrees per second. This is about 4.5X the speed of an air-powered system. This is VARIABLE speed in both directions with a joystick control. Return speed is about 20% faster than extend (bending) speed. This unit is powered in both directions, unlike the power systems most of our competitors import whole and resell!

OPTIONS:

*POWER UNIT: Our 2.0 HP power units have a 10 ft power cord and come installed with a NEMA 6-50 plug. Amp draw is approximately 12.3 Amps These power units are made here in the USA from components sourced from North America and Europe and feature a 1 year warranty, even in business use. They can be matched with our auto stop, and have a joystick valve for speed and direction control! You will need 220-250 volts AC to run this system. It can be configured to run on 208 volts as well. We can custom-build these for about $600 more with a 50 HZ specific motor for our customers in countries with 50HZ power.

*PRECISION AUTO STOP KIT- This infinitely adjustable auto-stop turns off the hydraulics when the machine reaches the pre-set stop point. Say goodbye to part variation, this will stop in the same place every time. All metal parts come nickel or zinc plated. Requires counter sinking 8 small holes (which are already cut in your machine from the factory, just not countersunk) to install. All wiring and plugs are included. This does NOT work with a pin in the 4.5 HD pressure die location. If you need to run your auto stop on parts that require 2 pressure dies for capacity reasons, you must make those bends on a 6-inch bend radius.

*CART BRACKETS: Just like you would expect, these allow you to hang your hydraulic power unit under the carts that we sell. Simple nuts and bolts installation once you drill 3 holes into your bender cart. Brackets are CNC laser-cut P&O steel and formed on a CNC press brake. Black powder coat finish. Slotted holes throughout for easy adjustment and flexibility of installation based on hole placement. ( These are available in the cart and storage section of the website.)

Notes- This cylinder with auto-stop does not fit in the machine with the Thin Wall Attachment (TWA). The thin wall attachment is no longer offered.

Machine hydraulic power requirements: The 1.5HP Elec/Hydro system draws ~8.1 amps at 220-250 volts AC. The 2.0 HP system draws ~12.5 amps at 220-250 volts AC. Our systems are designed for 60hz power (contact us for 50hz options if needed). They can also run on 208V power. We can wire our 2HP system for 110V at your request, but it pulls over 25A and is a highly unpopular configuration.

This system was designed from the ground up to be the optimal power source for our tubing bender. It is compatible with all revisions of our tubing bender. If you are tired of having operators in your shop scraping tubes and valuable parts, this solution can pay for itself in scrap reduction! DOM and stainless tubing costs money, and so does time. This upgrade saves both.

Subscribe to our YouTube channel for more videos on this excellent upgrade. We will make more videos soon; you will want to be notified.

LINK – click to visit us on YouTube

We use our electric/hydraulic system in this video when we teach novices how easy our setup is to use. Let us show you in under 7 minutes:

Want to see a whole project from start to finish, and even more bending tricks that are 100% unique to our design? Watch this video:

Here is a video showing how to make a roll bar (And using the 2 HP electric hydraulic system):

Please read our terms and FAQ for complete information about warranty, returns, and more.

3 reviews for 2.0 HP Electric/Hydraulic Power System & Components for M600 Series Bender